ACAS Compressed Air Audits

Compressed air is a major energy consumer in a plant, if not the largest. Despite its use across various manufacturing applications, it is the most misunderstood utility, yet has major potential for cost reduction. Fortunately, a compressed air audit can pinpoint opportunities for cost savings and help create a more streamlined and efficient operation.

Reduce Compressed Air Costs by 25-50% With an Air Audit

When looking to reduce operating expenses associated with compressed air, companies often overlook the potential savings through effective management of their compressed air systems. Experts estimate that a many users could cut their costs by 25-50%.

ACAS offers professional compressed air audits designed to uncover these cost reductions by assessing current flow rates, energy consumption, and operating pressure. These audits provide critical data for uncovering areas of improvement within your air system. Many plants currently operate with 50% more compressed air horsepower than necessary for their operations. An air audit not only results in operating cost reductions over time but also has a positive environmental impact.

Did You Know...

Some utility companies offer rebates that may cover the entirety of energy study expenses. Certain programs even offer financial support for energy-efficient projects. In some instances, these programs contribute up to 50% of the total project cost or provide incentives such as 12 cents for every kilowatt saved over the course of a year. This financial assistance highlights the commitment of utility companies to promote energy conservation initiatives and incentivize businesses to implement sustainable practices.

Get a Professional Air Audit with ACAS

Nearly all manufacturing facilities overspend on the operation and maintenance of their compressed air systems. Often time, this results in inadequate compressed air quality. This issue stems from a multitude of factors, including inefficient equipment choices, poor system design and layout, inadequate maintenance practices, inefficient compressor controls, and a lack of effective storage, among others—both past and current.

The skilled technicians at ACAS possess the knowledge to perform a comprehensive compressed air audit, utilizing gathered data to propose cost-saving alternatives.

Benefits of a Compressed Air Audit

- 25-50% Cost Savings

- Reduce the risk of equipment failure

- Reduce energy and repair costs

- Reduce energy consumption

- Increase productivity

- Reduce unplanned downtime

- Improve the quality of compressed air

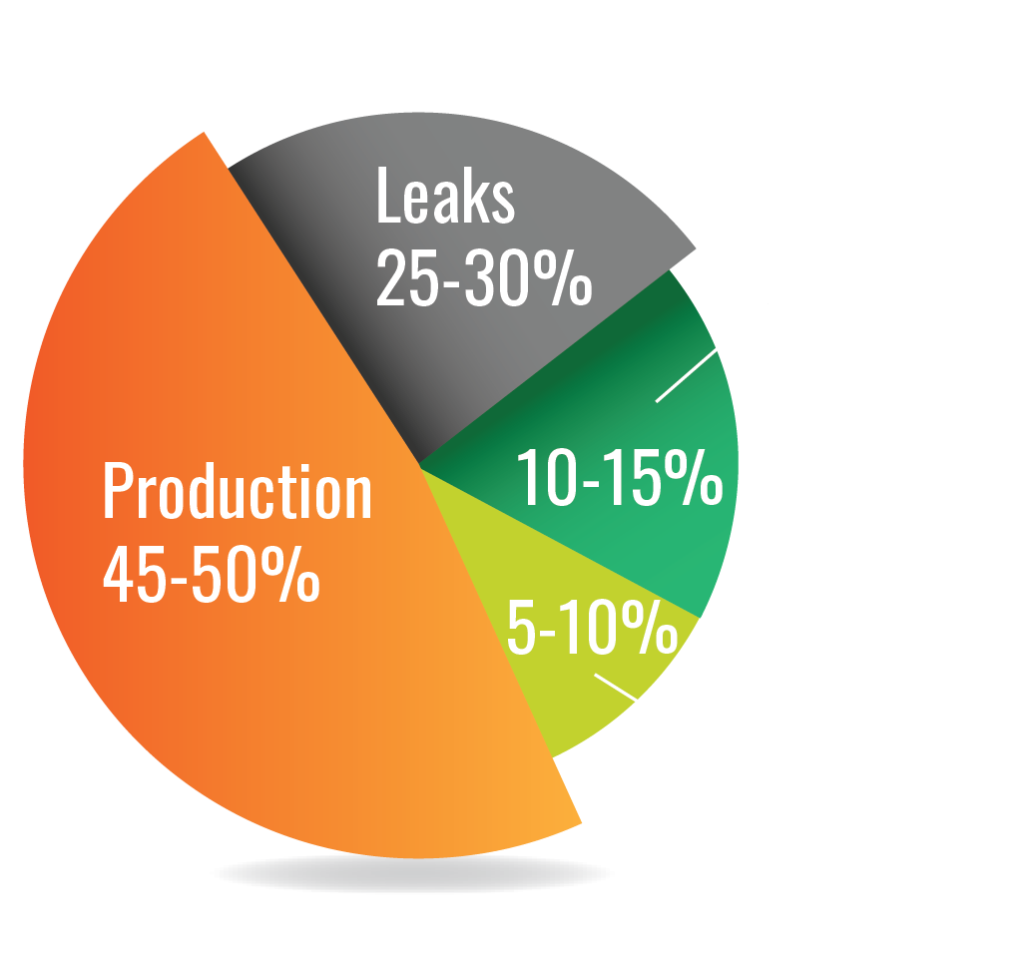

Where is Most Compressed Air Wasted?